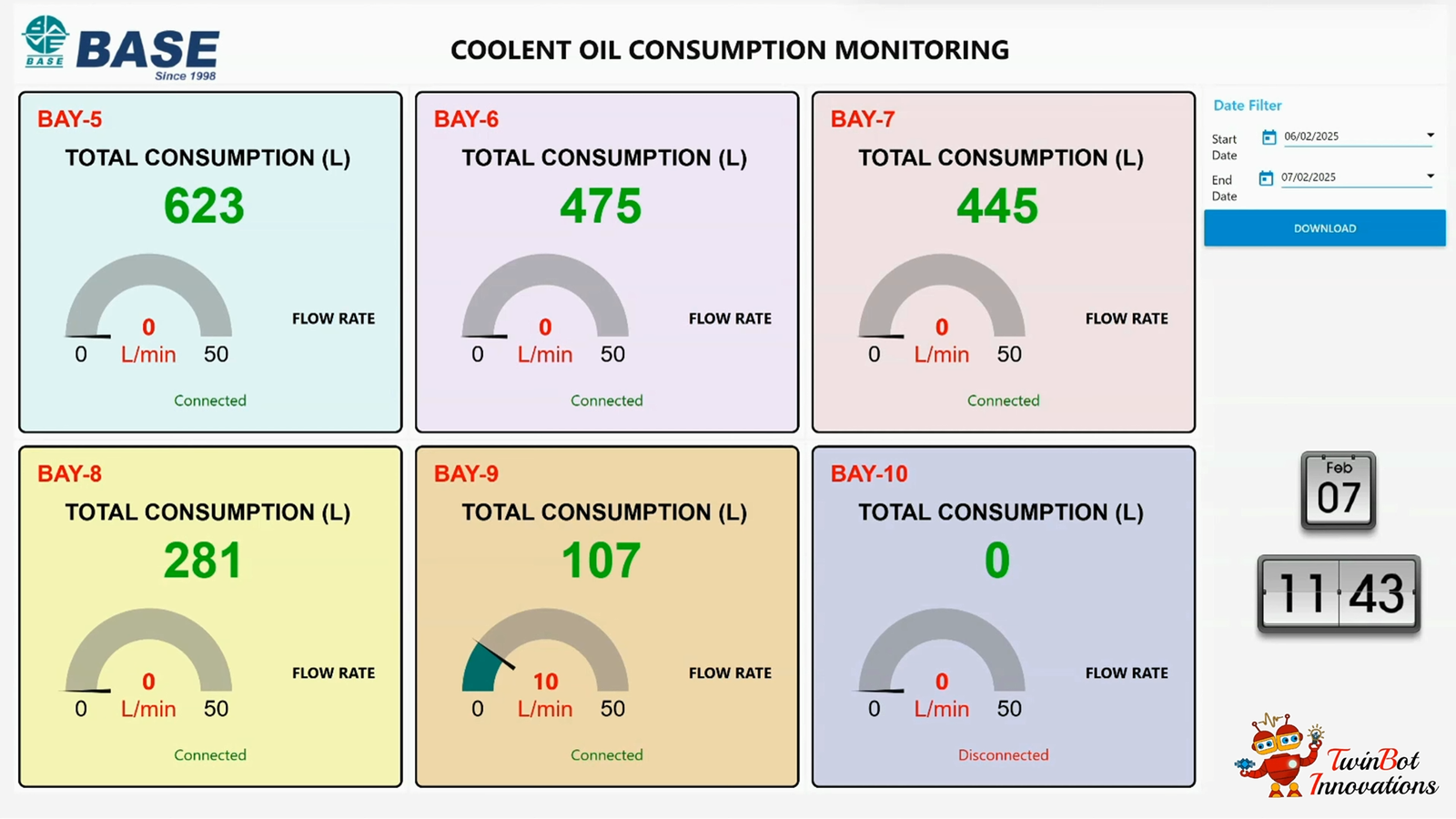

Live metrics, alarms, and guided actions.

Industrial Automation

Say Goodbye to PLCs. Step into the Future with ECS.

Replace high-cost PLC stacks with purpose-built Embedded Control Systems (ECS) and Sail OS dashboards that make automation simpler, faster, and easier to maintain.

Support-ready automation guidance.

Rugged ECS builds for harsh shop floors.

Lower PLC cost and faster decision cycles.

Why ECS Now

Programmable Logic Controllers (PLCs) have powered industry for decades, but they can be costly, rigid, and over-complex for many modern use cases. ECS offers a compact, flexible, and integration-ready path forward.

PLC vs ECS

See the difference in cost, integration, and control.

| Aspect | PLC | ECS |

|---|---|---|

| Cost and Maintenance | Higher cost with proprietary hardware; vendor-specific support and expensive spare parts. | Lower fixed cost for the same outcome; easier maintenance and more affordable spare parts. |

| Programming | Commonly ladder-logic focused; limits advanced workflows. | Supports modern stacks (C/C++/Python) for richer logic and integrations. |

| Size and Space | Bulkier, needs larger control panel footprint. | Compact designs fit tight panels and edge enclosures. |

| Reliability | Proven for harsh industrial environments. | Industrial-grade designs can match reliability with ruggedized hardware. |

| Scalability | Scaling can be costly and requires extra modules. | Flexible scaling with simpler expansion paths. |

| System Complexity | Custom setups often add modules and complexity. | Consolidated architectures keep systems simpler. |

| Customization | Designed for standard processes; less tailor-fit. | Fully customizable for your exact process and workflow. |

| Integration | Often needs add-on hardware for IoT/AI and modern sensors. | Integration-ready for IoT, analytics, and modern connectivity. |

| Environmental Impact | Higher energy draw with fixed industrial-grade components. | Energy-efficient designs reduce operating cost and footprint. |

Core Capabilities

Designed for production clarity and operational resilience.

Seamless Integration

Designed to slot into real production environments with clean wiring, clear UI, and stable protocols.

Easy to Use

Operator-first workflows that reduce judgement calls and make outcomes consistent.

Cross Compatibility

Built for retrofit and coexistence with existing sensors, tooling, and shop-floor constraints.

Scalable

Start small and expand without redesigning the whole control architecture.

Secure

Lock down settings and protect sensitive parameters with role-based access and guarded screens.

Robust and Cost-Effective

Durable hardware and practical packaging to deliver dependable automation without overpaying.

Sail OS: Clarity for Industrial Automation

Sail OS is a custom-built operating system for industrial automation. It converts complex factory signals into dashboards, insights, and actions your team can understand quickly.

Customizable and Intuitive Interface

Tailor control panels for your factory. Simple UI works for technical and non-technical teams.

Immersive HDMI Support

High-resolution views on external displays for clear monitoring on the shop floor.

How We Deliver

Fast, clear, and production-ready.

Connect

Share your requirements and desired features. We design a solution tailored to your workflow.

Integrate

We propose a timeline and deliver a personalized control panel after you approve the plan.

Streamline

We install, automate, and integrate into live production with stable results and minimal downtime.

Trusted By Teams In Production

Teams already trust TwinBot in production environments.

Talk with our automation voice assistant

Ask about products, ECS vs PLC, or request a custom quote in seconds.